Embarking on the journey of establishing a printing press business is both exciting and challenging. As an aspiring entrepreneur or small business owner, you’re stepping into an industry that, while traditional, continues to evolve with technological advancements and changing market demands.

One of the critical aspects of running a successful printing press operation lies in managing operational costs, ensuring timely delivery of services, and maintaining the reliability of your equipment. These factors are interconnected; inefficiencies in one area can ripple through the others, affecting your bottom line and customer satisfaction.

In this comprehensive guide, we’ll explore practical strategies to manage paper costs effectively, meet tight deadlines without compromising quality, and prevent equipment breakdowns that can halt your operations. By implementing these strategies, you can build a resilient and efficient printing press business poised for long-term success.

Managing Paper Costs

In the printing press business, paper expenses can quickly escalate, impacting your bottom line. However, with strategic approaches, you can effectively manage and reduce these costs without compromising on quality.

1. Implement Print Management Software

Utilizing print management software provides visibility into your printing operations. These tools track usage patterns, identify wasteful practices, and help enforce cost-saving measures. By analyzing this data, you can make informed decisions to optimize paper consumption.

2. Optimize Printer Fleet and Equipment Selection

Choosing the right equipment is crucial. Invest in printers that are energy-efficient and have duplex printing capabilities. Regularly assess your printer fleet to ensure each machine meets your current needs, avoiding unnecessary maintenance costs and energy consumption.

3. Reduce Paper Usage Through Duplex Printing and Digital Alternatives

Encourage duplex (double-sided) printing as a default setting to cut paper usage by up to 50%. Additionally, consider digital alternatives for internal documents, such as sharing files electronically, to further decrease paper consumption.

4. Utilize High-Yield and Compatible Toner Cartridges

Opt for high-yield toner cartridges, which, although more expensive upfront, offer a lower cost per page over time. Ensure compatibility with your printers to maintain print quality and avoid potential damage to equipment.

5. Regular Maintenance and Proper Use of Printers

Regular maintenance of your printers ensures they operate efficiently, reducing paper jams and misprints that lead to waste. Train staff on proper printer use and establish protocols for handling common issues to minimize downtime and paper loss.

By implementing these strategies, you can significantly reduce paper costs, contributing to a more sustainable and profitable printing press business.

Meeting Tight Deadlines

In the printing press business, meeting tight deadlines is crucial for maintaining client satisfaction and staying competitive. Delays can lead to lost clients and a tarnished reputation. Let’s explore strategies to ensure timely delivery without compromising quality.

1. Streamline Workflow Processes

Implementing an optimized workflow is essential. By automating routine tasks and reducing manual interventions, you can minimize errors and accelerate production. Utilizing workflow automation tools allows for efficient job scheduling and tracking, ensuring that each task progresses smoothly from initiation to completion.

2. Effective Scheduling and Time Management

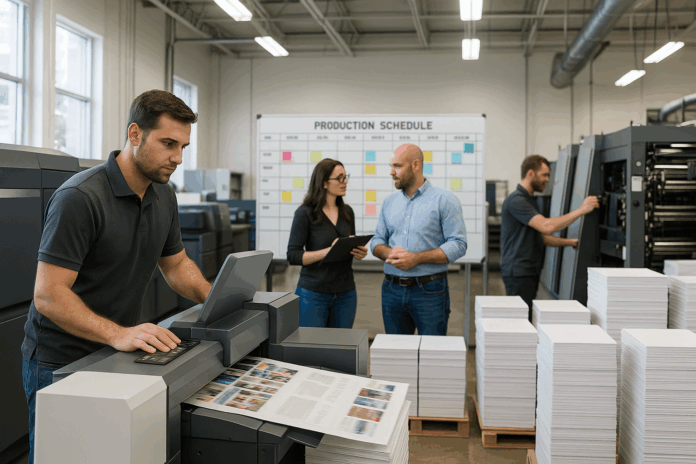

Developing a realistic production schedule is vital. Break down projects into manageable tasks, assign responsibilities, and set clear deadlines. Regularly review progress to identify potential bottlenecks early. Prioritize tasks based on urgency and complexity to allocate resources effectively.

3. Leverage Technology for Efficiency

Adopting advanced printing technologies can significantly reduce turnaround times. High-speed digital printers, automated finishing equipment, and real-time tracking systems enhance productivity. Investing in technology that integrates seamlessly with your workflow ensures that you can handle increased volumes without sacrificing quality.

4. Build a Reliable Team and Foster Communication

A skilled and cohesive team is the backbone of timely project delivery. Provide ongoing training to keep staff updated on the latest technologies and best practices. Encourage open communication to quickly address issues and adapt to changes. Regular meetings and feedback sessions can help maintain alignment and motivation.

By implementing these strategies, you can enhance your ability to meet tight deadlines, thereby improving client satisfaction and positioning your printing press business for sustained success.

Avoiding Equipment Breakdowns

In the printing press business, equipment reliability is paramount. Unexpected breakdowns can lead to missed deadlines, increased costs, and dissatisfied clients. Implementing a proactive maintenance strategy ensures your machinery operates efficiently and minimizes downtime.

1. Importance of Regular Preventive Maintenance

Preventive maintenance involves routine checks and servicing to prevent equipment failures. By adhering to a maintenance schedule, you can identify and address potential issues before they escalate. Regular tasks include cleaning, lubrication, and inspection of critical components. For instance, offset printing presses require consistent maintenance to ensure optimal performance and longevity.

2. Training Staff on Proper Equipment Use

Well-trained staff are less likely to misuse equipment, reducing the risk of damage. Providing comprehensive training on machine operation, safety protocols, and basic troubleshooting empowers employees to handle equipment responsibly. Continuous training programs are essential to keep up with technological advancements and maintain high operational standards.

3. Keeping a Maintenance Log and Schedule

Maintaining detailed records of all maintenance activities helps track equipment performance and predict potential failures. A maintenance log should include dates, tasks performed, parts replaced, and observations. Utilizing standardized log sheets for daily, weekly, and monthly checks ensures consistency and thoroughness in maintenance practices.

4. Partnering with Service Engineers and Technicians

Establishing relationships with professional service engineers provides access to expert knowledge and support. These specialists can perform complex repairs, offer technical advice, and assist in implementing advanced maintenance strategies. Companies like Veritek offer comprehensive engineering services tailored to the printing industry, ensuring your equipment remains in optimal condition.

By prioritizing preventive maintenance, investing in staff training, maintaining detailed logs, and collaborating with experts, you can significantly reduce equipment breakdowns. This proactive approach not only safeguards your machinery but also enhances overall productivity and client satisfaction.

Embarking on the journey of establishing a printing press business is both exciting and challenging. As we’ve explored, managing paper costs, meeting tight deadlines, and avoiding equipment breakdowns are pivotal aspects that can determine the success or failure of your venture.

Managing Paper Costs: Implementing strategies such as duplex printing, selecting economical fonts, and utilizing high-yield toner cartridges can significantly reduce expenses. Moreover, embracing digital alternatives and encouraging a paperless environment not only cuts costs but also aligns with sustainable practices.

Meeting Tight Deadlines: Efficiency is key. Streamlining workflow processes, leveraging technology, and fostering effective communication within your team ensures that projects are completed promptly without compromising quality. Remember, timely delivery enhances client satisfaction and builds trust.

Avoiding Equipment Breakdowns: Regular preventive maintenance, proper staff training, and maintaining detailed maintenance logs are essential. Partnering with reliable service engineers can provide the expertise needed to keep your equipment in optimal condition, minimizing downtime and ensuring consistent productivity.

By proactively addressing these areas, you’re not just mitigating risks; you’re setting a solid foundation for a resilient and efficient printing press business. Embrace these strategies, stay adaptable, and continually seek improvements. Your commitment to excellence will not only drive profitability but also establish your reputation in the industry.